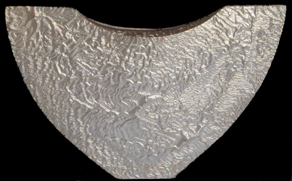

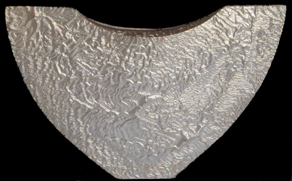

Reticulation Silver

(Image courtesy of Hauser & Miller customer's Paulette Myers.)

By annealing the silver several times and cleaning the surface after each annealing, the silver becomes ready to reticulate. As the silver is heated each time the copper oxidizes on the surface. After the surface is pickled and cleaned the copper is removed which leaves a surface nearly pure in silver content. This causes the surface to have a higher melting temperature than the alloy within. When the metal is heated one more time, to just below the flow point, the surface will become embellished with a vein-like texture. The number of anneals and the size of the flame used to reticulate cause variations in the texture of the reticulated surface.

Hauser & Miller is the original manufacturer of this alloy in the United States. We developed it at the request of Heikki Seppa. Heikki is a renowned artist/silversmith from Finland and a retired professor of art and metalsmithing at Washington University in St. Louis. Heikki brought this popular Scandinavian technique from Finland and he and his students have popularized it throughout North America.